Design of Tethered Expedition Robot (TReX) system for 3D mapping of steep terrain and harsh environment

Abstract: The use of tethers in mobile robots is a new way to safely explore steep terrain and harsh environments, which are considered too dangerous for humans and beyond the capabilities of standard ground rover. However, there are still major challenges in terms of mobility under tension, autonomous tether management, and methods of assessing the environment. As an incremental step to solve these problems, this article outlines the design and testing of a central pivot tether management payload that enables a four-wheel mobile robot to enter and map steep terrain. The selected design allows the tether to be attached and passively rotated near the center of mass of the ground vehicle in the direction of the applied pulling force. The existing design method in the tethered climbing robot is proposed for comparison. In the test of our integrated payload and rover, the Tether Explorer Robot (TReX) shows complete rotation freedom when under tension on steep terrain, and has basic autonomy in the flat tether management process. . The extension of tether management for steep terrain is also discussed. Finally, a planar lidar fixed on the tether shaft is used to demonstrate the 3D mapping function during the tether traversal. The visual ranging method is used to construct a local point cloud map at a short distance, and a variant of the iterative closest point (ICP) algorithm is used to reconstruct a globally aligned 3D map. The planar lidar fixed on the tether reel is used to demonstrate the 3D mapping function during the tether traversal. The visual ranging method is used to construct a local point cloud map at a short distance, and a variant of the iterative closest point (ICP) algorithm is used to reconstruct a globally aligned 3D map. The planar lidar fixed on the tether reel is used to demonstrate the 3D mapping function during the tether traversal. The visual ranging method is used to construct a local point cloud map at a short distance, and a variant of the iterative closest point (ICP) algorithm is used to reconstruct a globally aligned 3D map.

Related work

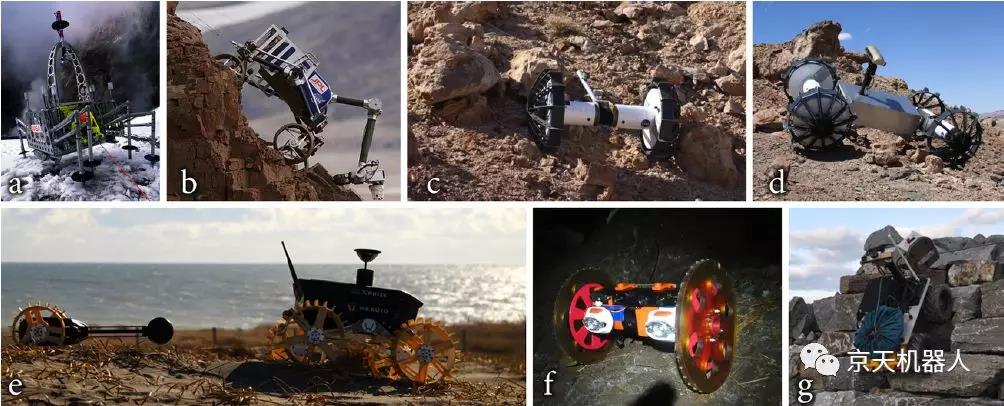

The prototype of the tether climbing robot is Dante II (Figure 2a), which is an eight-legged walking rover used to traverse the inner crater of a volcano [15]. Dante II successfully repelled the extreme slope and demonstrated the challenges/limitations of the restraint maneuver; during the ascent of the crater, Dante II fell while rotating outside the direction of the fall and was severely damaged.

The Exploration and Science Team Robot for Steep Areas (TRESSA) (Figure 2b) is the first modular system that allows connected ground mobile stations to enter vertical terrain [14]. The dual tether configuration managed off-board can be easily integrated with different rover vehicles and allows some lateral movement on steep terrain. However, multiple tethers mean that it is more difficult to navigate around obstacles, the tether is worn out, and the range due to dragging is reduced (the tether is not wrapped around the robot).

So far, the most capable tethered climbing robot is Axel II (Figure 2c), which is a two-wheeled mobile vehicle with a driven tethered caster arm [7]. Multiple Axel II rover can be linked by a docking station, used as a four-wheel rover (ie DuAxel), can also be used as a redundant base station and climbing rover (Figure 2d). Moonraker and Tetris robot 1 (Figure 2e) and VolcanoBot 2 (Figure 2f) use the innovative configuration of Axel II.

The vScout prototype (shown in Figure 2g) consists of the payload of a winch installed on the Clearpath Husky A200 rover. This prototype is the predecessor of TReX. Although the tether was not effectively managed on the car, vScout successfully proved the maneuverability of a 50 kg commercial unmanned vehicle on steep slopes.

Figure 2 Past and present tether climbing vehicles: a) Dante II [2], b) TRESSA [5], c) Axel II and d) DuAxel [7], e) Tetris and Moonraker [3], f) VolcanoBot II (JPL/CalTech), and g) vScout [13]

System design

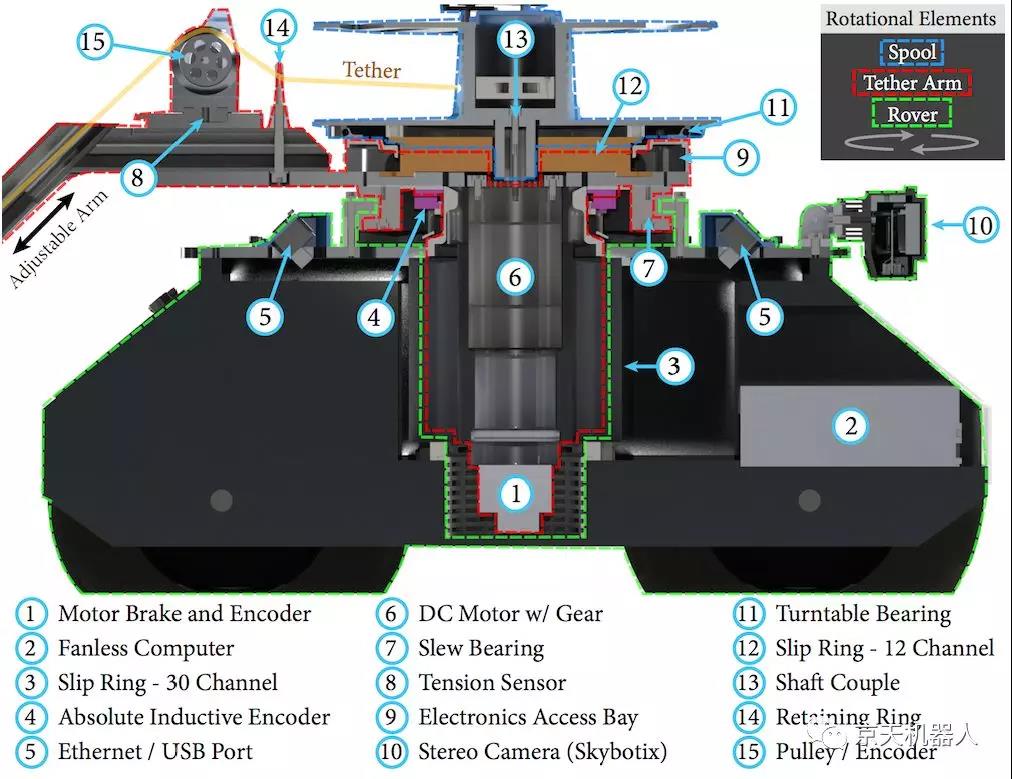

In order for the tether rotator to continuously rotate under tension, the tether is connected to a freely rotating joint. When tightening, the tension of the tether is aligned with the virtual line that intersects the center of mass of the vehicle. The on-board managed tether is wound on a drive spool, which is mounted on a swivel joint in the center of the Clearpath Husky A200 unmanned vehicle with anti-skid steering. The cross-sectional view of the TReX CAD model shown in Figure 3 illustrates the installation configuration of the spool on the rotating tether arm, which is mechanically connected to the rover through a slewing bearing. The three rotating elements (rover, tether arm and spool) are outlined with colored arms and can only rotate when driven by a motor. The motor suspended in the 10 cm cavity of the rotating slip ring is fixed to the tether arm, and its shaft is connected to the spool. To reduce the torque on the rover, the manually adjustable tilt arm allows load balancing with the center of mass of the vehicle. As long as there is sufficient wheel traction, the design can make the rover freely rotate without being affected by the applied tension.

Figure 3 Annotated CAD model (section view). The three rotating elements include the rover (green), tether arm (red) and spool (blue). The tether spool is only driven when it is electric. The main internal components are marked. Please note that the tether arm, lidar and rover wheel have been cropped

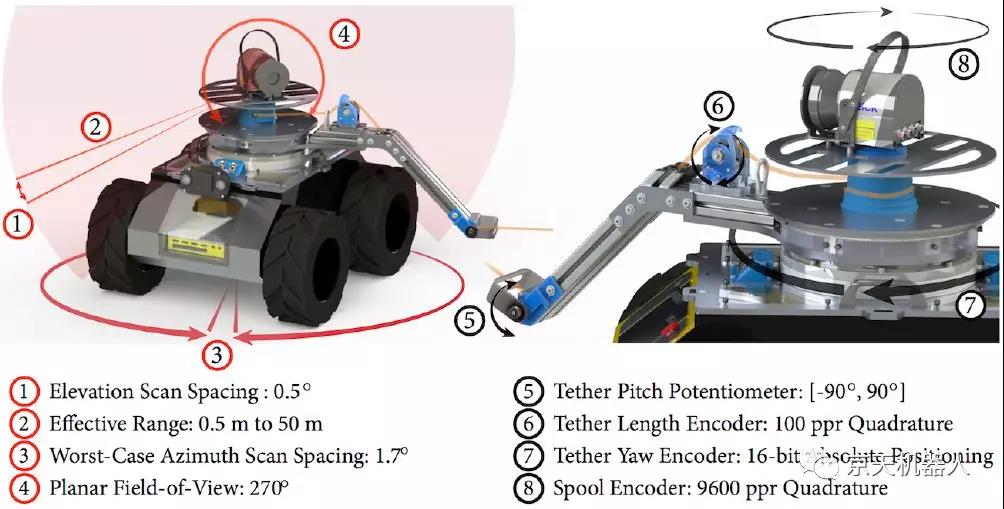

Figure 4 Left: 3D mapping details. The lidar plane is shown by an opaque red disc. Right: Tether direction and sensor specifications. The measurement positions of pitch, length and yaw are indicated. The spool encoder provides rotation measurement for lidar.

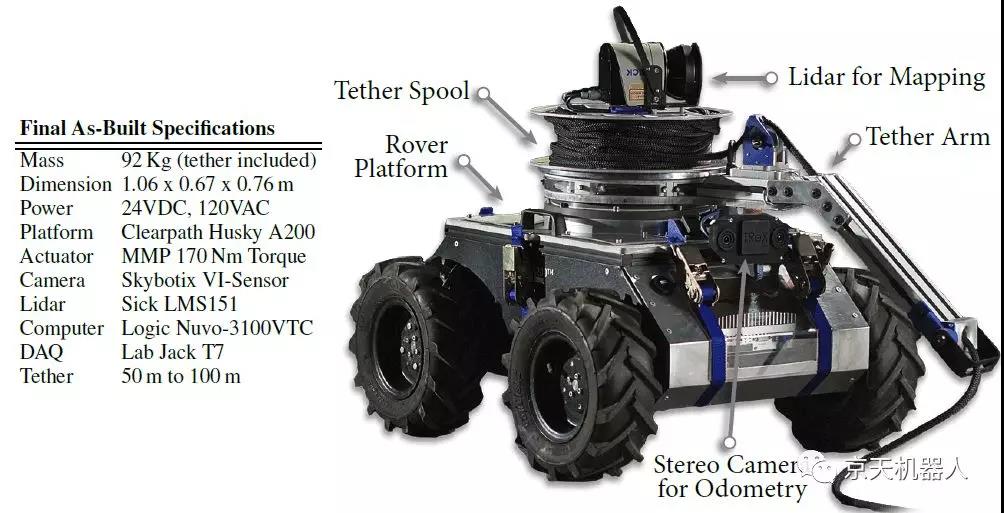

Figure 5 provides the built system specifications and the final build image. The payload is tailor-made for the Clearpath Husky A200 unmanned ground vehicle, as it has been successfully implemented in the vScout prototype.

Figure 5 Left: Final system parameters. Right: TReX with the main system label. We noticed that the stereo camera may be blocked by the restraint arm during the movement. However, the rotatable tether arm can reposition the rover and camera under pressure.

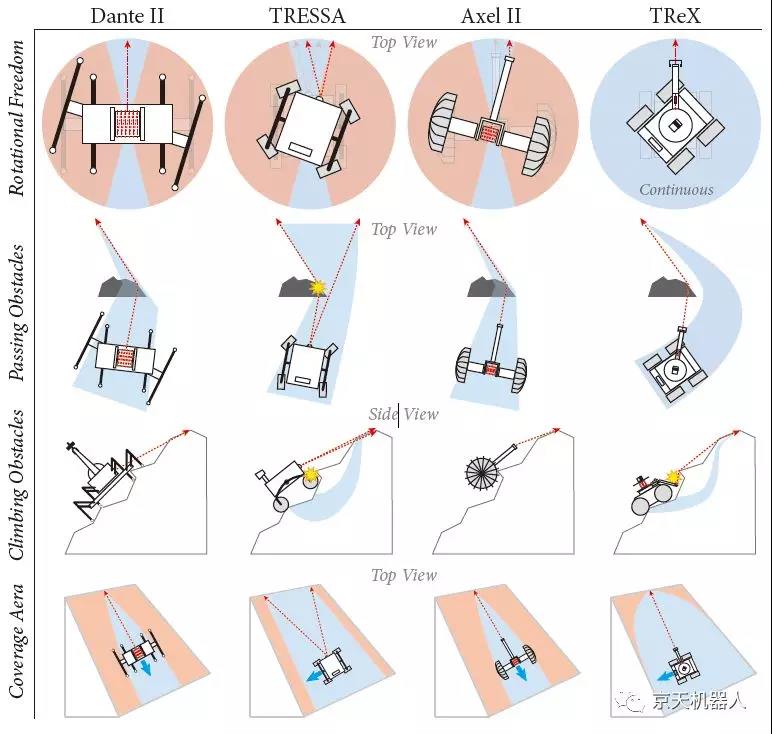

Figure 6 Comparison of maneuverability of Dante II, TRESSA, Axel II and TReX (the figure is not drawn to scale) Each row represents the attributes of tether mobility: degree of freedom of rotation, obstacles, climbing obstacles and coverage area (one way) ). Each column corresponds to a different vehicle. The view direction is given in rows (for example, top and side). Except for TRESSA, all vehicles manage the tether on the vehicle. The tether is represented by a red dashed line, and the interaction with obstacles is represented by a yellow asterisk. Light blue and red indicate feasible and unfeasible rotations/paths, respectively. The small blue arrow indicates the forward direction of the vehicle.

Experimental results

Let's take a look at the experimental results through the following video:

https://mp.weixin.qq.com/s/gJKrMkX_69PDO1SlnX5B-w

This video shows some of the highlights of a field test conducted in an old gravel pit in Sudbury, Ontario, Canada in June 2016. The Tethered Adventure Robot (TReX) is designed to run on steep and rough terrain by using ropes that can carry part of the load, provide power and transmit data to the operator. We proved that TReX can descend along multiple cliffs and other steep terrain to build 3D models. The Tether Adventure Robot (TReX) allows 3D mapping in steep terrain and harsh environments, and can be used for cliff exploration, dam safety inspection and disaster response.

Original paper:

McGarey P, Pomerleau F, Barfoot T D. System design of a tethered robotic explorer (TReX) for 3D mapping of steep terrain and harsh environments[C]//Field and Service Robotics. Springer, Cham, 2016: 267-281.

Donghu Robot Laboratory, 2nd Floor, Baogu Innovation and Entrepreneurship Center,Wuhan City,Hubei Province,China

Tel:027-87522899,027-87522877

Robot System Integration

Artificial Intelligence Robots

Mobile Robot

Collaborative Robotic Arm

ROS modular robot

Servo and sensor accessories

Scientific Research

Professional Co Construction

Training Center

Academic Conference

Experimental instruction

Jingtian Cup Event