Nuclear material handling and inspection

Overview:

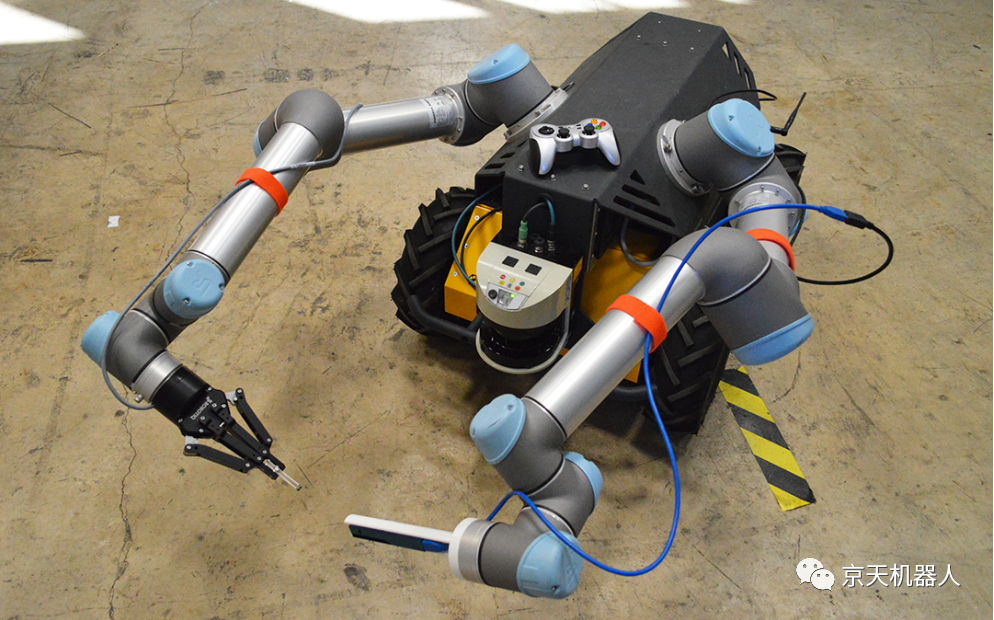

The task of the nuclear robotics team at the University of Texas at Austin is to develop an automated system by the Department of Energy for the recovery and processing of nuclear materials and the inspection of pollution incidents. As early as 2015, the research team turned to ClearPath's robot integration experts. They helped install two UR5 robotic arms on the Husky platform and created a unique industrial-grade dual-arm system named "VaultBot". This robot will help push the team's research towards the ultimate goal, which is to deploy life-saving autonomous robots.

“VaultBot” Mobile Manipulator

VaultBot mainly includes a four-wheel sliding Clearpath Husky mobile base platform, on which there are two 6-DOF Universal Robotics "UR5" manipulators mounted on custom partitions. The Husky base provides a wide and stable footprint. The solid base is sufficient to support the arms and its control box without any tilting, swinging or other forms of movement on the base. Likewise, the four wheels provide extra traction and redundant contact points, helping to navigate loose soil and/or debris, and minimizing the chance of the robot getting stuck. These wheels are driven by a differential steering system to minimize mechanical complexity and maximize durability and load capacity.

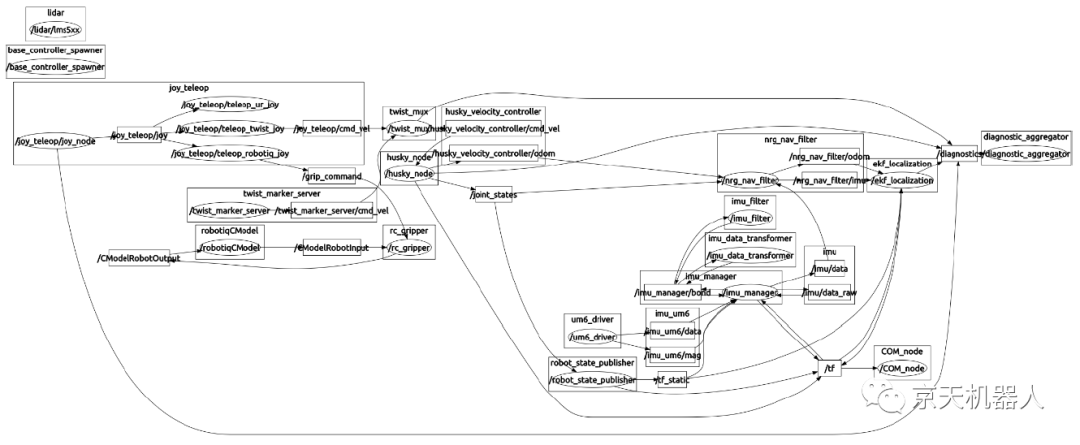

When the VaultBot starts, up to 21 such nodes will automatically run, control and connect and interface with the system, such as the onboard IMU, the joystick controller for remote operation and the SICK LIDAR LMS511 rangefinder, and perform diagnostics such as Tasks such as management and data filtering.

The Nuclear Industry and Applied Robotics Group is an interdisciplinary research group at the University of Texas at Austin. Mission: Develop and deploy advanced robotics technology in hazardous environments to minimize the risks for operators. Researchers completed rigorous interdisciplinary courses to understand the requirements for deploying systems in nuclear or other related fields. The depth and quality of the Cockrell Institute of Engineering and its faculty and staff ensure that they are qualified to develop various application fields (such as radiation, space, battlefield, medicine, oil exploration, etc.).

VaultBot ROSNode layout example

The system is based on ROS. One of the most beneficial aspects of ROS is the modular nature of its node/topic structure when combined with open source tasks. This means that if researchers or industry partners introduce new hardware, or new methods of interacting with or utilizing existing hardware, the software they write can be easily bundled to a ROS node or a series of nodes called "packages" middle. Then, anyone in the ROS community who needs it can use this package. It is even possible to share advanced decision-making or artificial intelligence architecture as a ROS software package for use by a larger community.

For more information about this project, please refer to:https://robotics.me.utexas.edu/

"Open the door" for safe recycling of nuclear waste

After building the VaultBot platform, the team did a series of research work. In 2018, the University of Texas "opened the door" for the safe recycling of nuclear waste. The team represented by Andy Zelenak (postdoctoral) and Mitchell Pryor (research scientist) is using VaultBot (Husky-based mobile manipulation platform for processing nuclear waste and other materials harmful to humans) to achieve this goal.

The main focus of the VaultBot project is mobile operations. The robot is good at contact tasks, such as turning valves, buttons, closing high-pressure switches and opening doors. The robot was originally designed to retrieve nuclear material from the vault of Los Alamos National Laboratory. The radiation dose rate in the vault is not enough to harm humans immediately, but even if it exceeds a few hours, exceeding the annual dose limit may still be a problem for humans.

Click to watch the video:This video illustrates the process of using real-time slow motion to open a door in ROS

The Husky chassis of VaultBot is equipped with dual UR5 manipulators and RealSense D435 depth camera. In terms of technical processes, VaultBot performs SLAM (simultaneous localization and mapping) and task planning, but its first task is manipulation. The team has been studying the real-time, reactive power control of the manipulator in ROS, which is very important when it comes to environmental contact.

Zelenak said: "We are working hard to promote the development of ROS so that anyone with a ROS robot can perform seemingly simple things, such as opening doors." "A few years ago, only a very large and well-funded team in the DARPA Robotics Challenge could handle these contact tasks. In a few years, I expect dozens of teams around the world will be able to do this." Most of the software is open source and can be found here.

Of course, this project involves many challenges. Although many of the issues related to the deployment of robots in Los Alamos are related to safety, while those related to robots (for example, restrictions related to wireless communication and cameras) are more related to safety, there are still some technical challenges . The action of the rotary valve is easy for humans, but it is still very difficult for robots. Many things need to be done. Some of the challenges the team faced were:

Find the goal in the space and plan the path to the goal;

Calculate the basic position where the goal can be reached;

Real-time visualization of the reach of the arm;

Ensure that the arm's movement plan is good;

Deal with uncertainty, especially after contact with the environment. Large-scale systems can be built quickly!

Develop improved supervisory control technology to handle complex environments, tasks and improved error recovery. The function of the robot has been rapidly improved, and the state machine is no longer applicable.

The improved man-machine interface is suitable for various levels of autonomy, from pure remote operation to monitoring of large autonomous systems.

Clearpath helps meet these challenges through a proven ROS-enabled mobile robot platform. Zelenak said: "Reliability is very important to us. Fixing hardware failures on other robots will take a lot of time. We would rather spend a lot of time researching. He added: "I believe VaultBot is the first dual-arm sold by Clearpath. Ha Husky, Clearpath cooperated with the university to complete the system design and meet our requirements. We like the fact that the UR5 robotic arm is industrial grade, and all parts of the robot can easily interact with ROS. "

Through this project, the group has established a new industry partnership with an international company, and the company is rapidly developing powerful mobile operating functions. The company is studying how to use the Clearpath platform for remote inspection and maintenance of its facilities.

The Nuclear Industry and Applied Robotics Group and VaultBot are both very famous. The paper published by the group at the 2018 WM Symposium was selected as an excellent paper. The team was also selected to participate in the inspection and maintenance robot conference at the 2018 Sprint Robotics Conference. In the past year, three other publications included:

1.Valner, R., Kruusamae, K., and Pryor, M., “TeMoto: Intuitive multi-range telerobotic system with natural gestural and verbal instruction interface,” Robotics, 7(1):9 (21 pages), February 2018. (featured cover article)

2.Vunder, V., Valner, R., McMahon, C., Kruusamae, K, and Pryor, M., “Improved situational awareness in ROS using panospheric vision and virtual reality,” The 11th IEEE International Conference on Human System Interaction , Gdansk, Poland, July 2018.

3. Valner, R., Vunder, V., Zelenak, A., Pryor, M., Aabloo, A., and Kruusamae, K., “Intuitive'human-on-the-loop' interface for tele-operating remote mobile manipulator robots,” International symposium on artificial intelligence, robotics, and automation in space (i-SAIRAS), Madrid, Spain, June 2018.

The team is preparing several papers for ICRA2019 (International Conference on Robotics and Automation), one of which discusses the real-time control of manipulators in ROS and how to help complete tasks such as opening doors.

Donghu Robot Laboratory, 2nd Floor, Baogu Innovation and Entrepreneurship Center,Wuhan City,Hubei Province,China

Tel:027-87522899,027-87522877

Robot System Integration

Artificial Intelligence Robots

Mobile Robot

Collaborative Robotic Arm

ROS modular robot

Servo and sensor accessories

Scientific Research

Professional Co Construction

Training Center

Academic Conference

Experimental instruction

Jingtian Cup Event